Showing 1–10 of 28 results

Transform your elevator system with Arkel ARCODE – the complete integrated solution combining VVVF drive technology, intelligent control systems, and advanced safety features. From small residential to large commercial buildings, ARCODE delivers superior performance and reliability.

✓ Same-Day Shipping | ✓ 2-Year Warranty | ✓ Expert Technical Support | ✓ Best Price Guarantee

Meet the brain and heart of your elevator system: the Arkel ARCODE Integrated Elevator Control Units. Revolutionizing the industry, ARCODE eliminates the complexity of traditional elevator panels by combining the motor driver (VVVF), control card, and emergency rescue system into a single intelligent and compact package. This integrated approach saves you time, cost, and space at every stage of your project while offering passengers unparalleled travel comfort and safety.

Chapter 1: Arkel ARCODE: A Paradigm Shift in Elevator Control

At the heart of modern vertical transportation systems lies a complex control unit that manages the elevator's every movement, safety, and efficiency. Traditionally, these systems were assembled from separate components such as the motor driver, main control board, and emergency rescue mechanisms. However, Arkel ARCODE fundamentally changes this fragmented structure by offering an integrated solution that sets a new standard in the industry. This chapter provides an in-depth examination of ARCODE's "Integrated Elevator Control Unit" concept and the strategic advantages brought by this integration.

1.1. Definition of the Integrated Control Unit: Three-in-One Power

Arkel ARCODE is a revolution in elevator technology, primarily combining three critical components into a single, compact, and synchronized package. This integrated structure significantly enhances the system's performance, ease of installation, and reliability.

-

- Motor Driver (VVVF Inverter): The powerhouse of the system, the VVVF (Variable Voltage Variable Frequency) inverter precisely modulates the power supplied to the elevator motor. This allows for millisecond-level control over the motor's speed, torque, and acceleration, ensuring a smooth and comfortable ride. ARCODE's integrated driver is designed to be fully compatible with both modern synchronous (gearless) motors and older generation asynchronous (geared) motors.

-

- Controller (Control Board): Acting as the brain of the system, the control board manages all logical operations. It processes calls from the floors and cabin, controls the opening and closing of doors, continuously monitors the status of the safety circuit, and makes all operational decisions for the elevator. In ARCODE, this logic center is located on the same hardware as the driver, enabling instantaneous communication and data exchange between them.

-

- Emergency Evacuation System (Rescue System): In emergencies like a power outage, the safe evacuation of passengers is of vital importance. While traditional systems require a separate rescue box or additional hardware for this function, ARCODE has incorporated this system internally. When powered by a UPS (Uninterruptible Power Supply) or a battery bank, ARCODE automatically switches to rescue mode and safely brings the car to the nearest floor or a pre-determined evacuation floor.

As seen in the product images, combining these three essential functions into a single body not only results in a compact unit that occupies less physical space but also eliminates the complex wiring between components.

1.2. The Strategic Advantage of Integration

ARCODE's integrated structure is not just an engineering choice but a strategic decision that offers tangible benefits to elevator installation, modernization, and maintenance companies.

-

- Flawless Synchronization: In systems where drivers and controllers from different manufacturers are used together, communication protocols, signal delays, and compatibility issues are common. This can lead to performance degradation, reduced travel comfort, and malfunctions. ARCODE's integrated nature guarantees that the driver and controller work in perfect harmony. This complete synchronization delivers a seamless, smooth travel experience during starts and stops.

-

- Simplified Installation and Reduced Space Requirement: Fewer components mean less wiring and a simpler assembly process. This is a critical advantage, especially in machine-room-less (MRL) elevator applications. In MRL systems, the space allocated for the control panel is extremely limited, and ARCODE's compact design offers an ideal solution for such projects. A shorter installation time translates directly into labor cost savings for installation companies.

-

- Increased Reliability: As the number of components in a system increases, so does the number of potential failure points. By offering an integrated solution tested as a single unit in a factory environment, ARCODE minimizes the risks of failure that can arise from the combination of different parts. This increases the overall reliability and uptime of the system.

-

- The Foundation of Smart Automation: This integration is not just physical but also a logical whole. The driver's real-time access to motor current and encoder data allows the controller to instantly process this information and dynamically calculate travel curves. This deep integration forms the basis for advanced digital commissioning procedures like "Auto-Tune" and "Shaft Learning," which will be detailed in the following chapters.

Chapter 2: The Technological Core: Performance and Innovation

Arkel ARCODE is more than just a unit that combines components; it possesses a series of innovative technologies that fundamentally improve elevator performance and efficiency. These technologies enhance the comfort of end-users—the passengers—and simplify the work of technical teams responsible for installation and maintenance.

2.1. The "Direct Landing" Principle: Redefining Travel Comfort and Efficiency

One of ARCODE's most distinctive and market-differentiating features is its "Direct Landing" technology. This technology eliminates one of the biggest inefficiencies of traditional VVVF systems.

-

- Technical Analysis: Traditional elevator control systems significantly reduce speed when approaching a floor and then search for the floor level at a very slow speed known as "creeping." This creeping phase causes both a loss of time and an uncomfortable stopping sensation for passengers. ARCODE, on the other hand, uses precise position data from the motor encoder to instantaneously calculate the distance to the destination floor for each trip. With this data, it dynamically determines the optimal point to begin deceleration and brings the elevator to a stop directly at the floor level in a single, smooth motion. The creeping phase is completely eliminated.

-

- Benefit Analysis:

-

- Superior Comfort: The absence of the jolt and slowdown experienced when transitioning to creep speed provides an extremely smooth and comfortable stopping experience for passengers.

-

- Reduced Travel Time: Eliminating the creeping phase at every floor significantly shortens total travel times, especially in high-rise and high-traffic buildings. This directly increases the efficiency of transportation within the building.

-

- Simplified Installation: In traditional systems, magnetic switches or flags placed in the shaft to determine slowdown points must be precisely adjusted. This is a time-consuming process that requires experience. Since ARCODE automatically detects the slowdown points, it eliminates the need for such mechanical adjustments, simplifying and speeding up the installation.

-

- Benefit Analysis:

2.2. Universal Driver Capability: The Key to Modernization

One of ARCODE's most strategic capabilities is its flexibility to drive both modern and older technology elevator motors. This universal compatibility makes it an invaluable tool, especially for modernization projects.

-

- Supported Motor Types: ARCODE can seamlessly control new-generation, high-efficiency Synchronous (Gearless) machines as well as the less efficient Asynchronous (Geared) machines commonly found in older buildings.

-

- Encoder Interface Cards: This flexibility is achieved through special encoder interface cards. The system uses the ENCA (Encoder Absolute) card for high-resolution absolute encoders (like EnDat, SSI, SinCos, BISS) used in modern synchronous motors. For incremental encoders (like 5V TTL, 10-30V HTL) found in older asynchronous motors, the ENCI (Encoder Incremental) card is used.

-

- Phased Modernization Strategy: In an elevator modernization project, one of the highest cost items is replacing the motor. Many old buildings have asynchronous motors that are still mechanically functional but are energy-inefficient and offer poor travel comfort. ARCODE provides building owners and modernization companies with a cost-effective "phased modernization" path.

-

- Phase 1 (Control System Upgrade): In the first phase, only the existing old control panel is removed and replaced with an ARCODE unit (along with an ENCI card). This alone provides immediately noticeable improvements such as direct landing, better safety features, and increased energy efficiency. The existing asynchronous motor and mechanical components remain in place.

-

- Phase 2 (Motor Replacement): When the budget allows or in subsequent years, the old asynchronous motor can be replaced with a modern and efficient synchronous motor. At this stage, there is no need to replace the ARCODE unit entirely. Simply, the ENCI card is removed and replaced with an ENCA card, and the system is re-configured for the new motor.

-

- Phased Modernization Strategy: In an elevator modernization project, one of the highest cost items is replacing the motor. Many old buildings have asynchronous motors that are still mechanically functional but are energy-inefficient and offer poor travel comfort. ARCODE provides building owners and modernization companies with a cost-effective "phased modernization" path.

This approach significantly reduces the initial cost of modernization, allowing a broader market to upgrade old elevator systems to current safety and performance standards.

2.3. Smart Automation: Reducing Labor and Preventing Errors

The traditional elevator commissioning process requires skilled technicians to spend hours, or even days, on manual adjustments and tests. ARCODE digitizes and automates this process, providing a revolutionary efficiency boost for installation companies.

-

- Motor Auto-Tune: In this process, one of the first steps of installation, the technician does not need to manually enter the complex electrical parameters (stator resistance, inductance, etc.) from the motor's nameplate. ARCODE learns these characteristics on its own by sending a series of test signals to the motor. This "Auto-Tune" process ensures that the motor is driven with the most optimal torque and current values, maximizing performance and eliminating the risk of human error.

-

- Digital Shaft Learning: This process creates a digital map of the entire shaft with a single trip of the elevator. As ARCODE moves the car from the bottom floor to the top, it uses precise data from the encoder to record the exact position of each floor, the distances between floors, and the locations of limit switches with millimeter accuracy. This completely eliminates the need for manual measurement and adjustment and ensures the system always knows the exact location of the car.

-

- Anti-Rollback & Pre-Torque: Just before the elevator is about to start, and before the brakes are released, ARCODE weighs the load inside the car. Based on this load, it calculates the exact amount of torque required to hold the car stationary and applies it to the motor. The moment the brakes open, the motor is already producing the correct torque, so there is no rollback or sudden jolt in the car. This feature is a significant detail that enhances comfort, especially in high-rise buildings.

These automated processes significantly reduce the hours of skilled labor spent on the installation site. Faster commissioning allows installation companies to complete more projects in the same amount of time, increasing their profitability. Furthermore, the standardization of the process and the reduction of human error risk improve the initial installation quality and decrease subsequent service calls.

Chapter 3: The ARCODE Ecosystem: A Modular Architecture over CANbus

Arkel ARCODE is not just a standalone product but the center of an integrated ecosystem of modular components that communicate seamlessly with each other. The backbone of this ecosystem is CANbus, a reliable and robust serial communication protocol widely used in industrial automation.

3.1. System Architecture Overview

The system diagram clearly illustrates the structure of the ARCODE ecosystem. The centrally located ARCODE unit communicates with peripheral units via two separate CANbus lines: one for the shaft wiring and one for the car wiring. This architecture offers numerous advantages over traditional parallel wiring systems:

-

- Reduced Wiring: Instead of running individual cables for each button, indicator, and sensor, all units are connected to the system via a single 4-wire CANbus cable. This dramatically reduces cable costs, labor, and potential connection errors.

-

- Noise Immunity: CANbus uses a differential signaling structure designed to ensure reliable data transmission even in electrically noisy environments like an elevator shaft.

-

- Flexibility and Expandability: Adding a new landing call station or an additional function card to the system is as simple as connecting the new unit to the CANbus line and updating the system software.

3.2. Analysis of Peripheral Units

The ARCODE ecosystem consists of various peripheral units, each designed to perform a specific task. Each of these units is critical to the overall functionality of the system. The following table summarizes these key components and their functions.

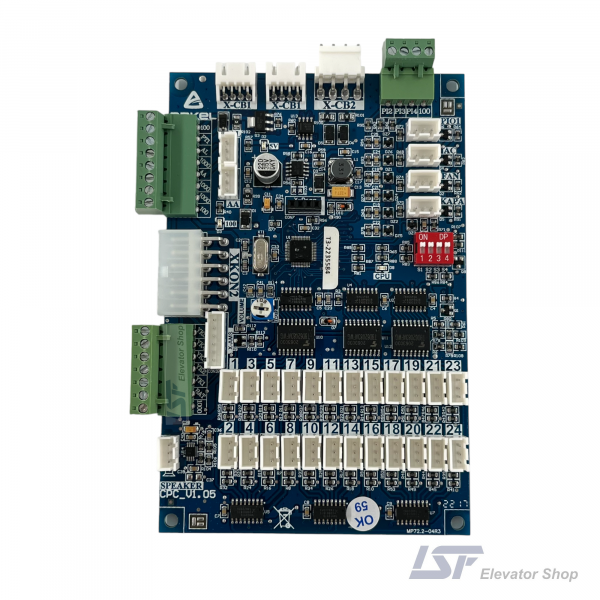

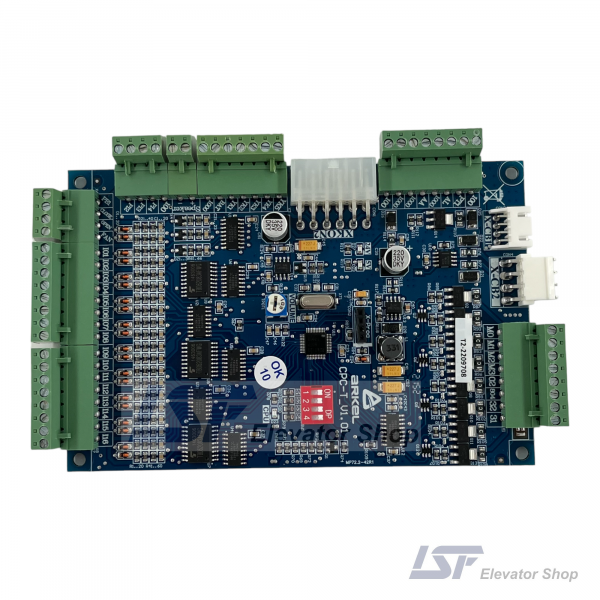

This modular structure allows the system to be scaled according to different needs. For example, a single CPC-T card may be sufficient for a simple residential elevator, while multiple CPC cards can be used for a 64-stop, double-door skyscraper project. The fact that all these components are designed by Arkel guarantees that the system works in holistic harmony. The requirement for a technician to use Arkel's special AREM handheld terminal to install, adjust, and diagnose the system demonstrates how integrated and holistic this ecosystem's design approach is. When an installation company or building owner invests in the ARCODE platform, they are not just buying a control unit, but an entire technology platform that will provide support, spare parts, and upgrades throughout the elevator's life cycle. This creates the potential for a long-term customer relationship for vendors, rather than a one-time sale.

Table 1: ARCODE Peripheral Unit Functions:

| Component Name | Full Name | Function | Connection Type |

|---|---|---|---|

| ARCODE | Integrated Control Unit | The central brain of the system; includes the VVVF driver, controller, and rescue system. | Main Power, Motor, CANbus |

| ENCA | Encoder Absolute | Processes absolute encoder signals for synchronous (gearless) motors. | ARCODE (Internal Connector) |

| ENCI | Encoder Incremental | Processes incremental encoder signals for asynchronous (geared) motors. | ARCODE (Internal Connector) |

| IBC-S | Inspection Box Controller | Car top inspection box board; the main communication hub between the car and the shaft. | CANbus |

| CPC / CPC-T | Car Panel Controller | Connection board for the car operating panel (COP) buttons. | IBC-S (Serial) / CANbus |

| FX-CAN | Flexible CAN Controller | A flexible car control board that combines some features of IBC-S and CPC. | CANbus |

| MSP-16 / MSP-32 | Multi-Serial Port | Integrates parallel-wired landing call buttons into the CANbus system. | CANbus |

| BC-BUT / BC-D2X / BC-LCD | Button Controller | Smart landing call buttons and indicators that connect directly to the CANbus line. | CANbus |

| IO-0210 | Input/Output Card | Provides extra programmable inputs and outputs for special functions. | CANbus |

| AREM | Arkel Remote Terminal | The mandatory handheld terminal for system installation, adjustment, fault diagnosis, and software updates. | CANbus |

| DBR | Dynamic Braking Resistor | Dissipates excess energy generated during regenerative braking by converting it to heat. | ARCODE (Power Terminals) |

Chapter 4: Practical Applications and Target Environments

ARCODE's flexible architecture and scalable structure make it a suitable solution for a wide variety of vertical transportation projects. It can be used in a broad spectrum of applications, from newly constructed modern skyscrapers to the renovation of old elevators in historic buildings.

4.1. New Elevator Installations (MRL and Traditional)

In new construction projects, speed, efficiency, and space utilization are the most important factors. ARCODE offers significant advantages in all three areas.

-

- Machine-Room-Less (MRL) Projects: MRL elevators, which are becoming increasingly popular in modern architecture, require all equipment to be located within the elevator shaft. ARCODE's combination of the motor driver, controller, and rescue system into a single compact unit significantly reduces the panel size required for such projects. Additionally, the CANbus-based serial wiring reduces cable clutter and installation time within the shaft, simplifying and accelerating MRL installations.

-

- Traditional Machine Room Projects: Even in systems with machine rooms, the efficiencies brought by ARCODE are valid. Smart automation features (Auto-Tune, Shaft Learning) shorten the project's commissioning time, helping construction companies meet their schedules.

4.2. Modernization and Retrofit Projects

One of the areas where ARCODE excels is the modernization of existing elevator systems. The phased modernization strategy, detailed earlier in Chapter 2.2, offers great financial flexibility to building owners and managers. Consider a 30-year-old building with a geared (asynchronous) motor elevator. This elevator's control system may not meet current safety standards (e.g., EN 81-20), is likely energy inefficient, and may break down frequently. With ARCODE, this system can be modernized without straining the budget. In the first stage, simply replacing the old panel with ARCODE instantly improves the elevator's safety, performance, and comfort. A larger investment, such as replacing the motor, can be postponed to a future budget period. This approach offers a practical and achievable roadmap for making millions of elevators in old buildings safer and more efficient.

4.3. Market Segmentation and Licensing

Arkel employs a smart software-based licensing model to ensure the ARCODE platform can cater to the needs and budgets of different market segments. Although the physical hardware remains largely the same, the system's capabilities are determined by software via a "dongle" (license key). This allows the product to be priced competitively for projects of different scales.

-

- BASIC License: This entry-level license is typically designed for low-rise residential buildings or small commercial structures. Features such as the number of stops (max. 16), car speed (max. 1.6 m/s), and group operation capacity (max. 2 elevators) are limited.

-

- MEDIUM License: Suitable for mid-sized office buildings, hotels, or more intensive residential projects. It offers more stops (max. 24), higher speed (2.5 m/s), and larger group operation (max. 4 elevators) compared to the BASIC level.

-

- HIGHLINE License: This is the top-tier license for high-rise buildings, large shopping malls, hospitals, and projects requiring complex group operations. It supports up to 64 stops, speeds up to 4 m/s, and group operation of up to 8 elevators. Special functions like firefighter's lift, emergency calls, and VIP calls are also activated with this license.

This licensing model allows customers to pay only for the features they need. Furthermore, if a project's needs change over time (e.g., a new elevator is added to a building), it is possible to upgrade the existing system's license. This creates business potential for vendors beyond the initial sale, for future upgrade and expansion projects. The system will not operate without a license key and enforces this requirement by giving an error code (Er71: License key not found) if the wrong license is used.

Chapter 5: Technical Specifications and Model Selection Guide

Choosing the right control unit for an elevator project is directly related to the motor's technical requirements. The ARCODE series offers various models with different power and current capacities, meeting the needs of everything from small residential elevators to high-speed commercial elevators. This chapter presents a comparative overview of the technical specifications of the 400V series models that the user sells and provides guidance on how to select the correct model.

The following table compares the ARCODE 400V series models based on the most critical parameters a technical buyer needs in their decision-making process: nominal and maximum output currents. The correct model is the one that best matches the nominal current (Inom) value specified on the elevator motor's nameplate. The maximum output current indicates the capacity to handle the instantaneous high current required during the elevator's start-up and acceleration phases.

Table 2: ARCODE 400V Series Technical Comparison

*Note: Maximum output current data for the 4B10A model was not found in the provided documents, but it is typically around twice the nominal current.

5.1. Application Analysis by Model

-

- 4B Series (10A, 14A, 17A, 26A): This series includes the most versatile and widely used models in the ARCODE product line. They offer an ideal cost/performance balance for low and mid-rise residential buildings, small offices, and light commercial applications. The 10A model is sufficient for the smallest motors, while the 26A model can comfortably operate higher-capacity or slightly faster systems.

-

- 4C Series (35A, 50A): With higher current capacities, this series targets larger commercial buildings, hotels, shopping malls, and elevators requiring medium speeds. They provide the necessary power to support heavier cars and higher carrying capacities.

-

- 4D Series (75A): This series is ARCODE's high-performance solution. It is designed for the most demanding applications, such as high-speed passenger elevators, large freight elevators in heavy industrial facilities, or car elevators in parking garages. Its capacity to drive motors requiring high torque and power makes it indispensable for special and challenging projects.