Showing all 8 results

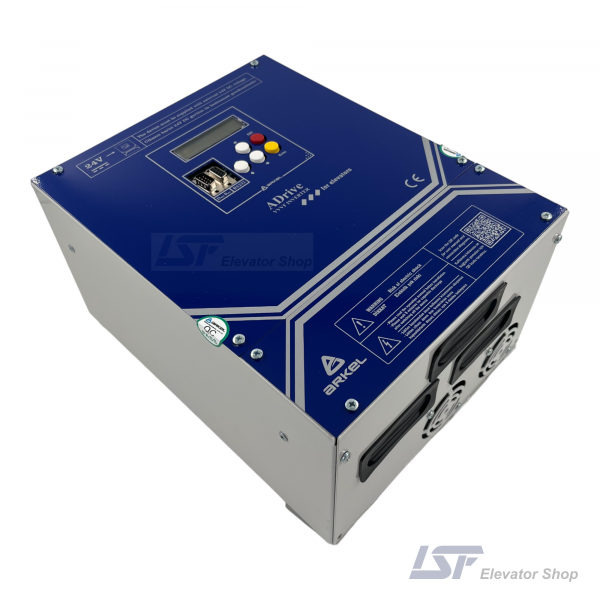

The Arkel ADrive series offers high-performance Variable Voltage Variable Frequency (VVVF) inverters designed specifically for the demanding requirements of modern elevator systems. Capable of driving both synchronous (gearless) and asynchronous (geared) motors, these drives ensure precise floor leveling, superior ride comfort, and significant energy savings for residential and commercial lifts.

- Application: Dedicated VVVF speed control unit optimized for elevator systems, ensuring smooth start/stop and travel comfort.

- Motor Compatibility: Supports both asynchronous (induction) open/closed loop motors and synchronous (permanent magnet) gearless motors.

- Key Features: Anti-rollback function without load cell, static auto-tuning, and vector control for high-torque performance.

- Emergency Rescue: Supports 60-120V battery packs or 220VAC UPS for automatic evacuation driving in case of power failure.

- Connectivity: Features RS-485 serial communication with ARL-500 controllers and supports various encoder interfaces (EnDat, SSI, SinCos with ENCABIT-Plus).

Arkel ADrive VVVF Inverters for High-Performance Elevators

The Arkel ADrive series represents a sophisticated solution for elevator motor speed control, designed to meet the rigorous standards of modern vertical transportation. Whether upgrading an existing geared system or installing a new gearless traction lift, the ADrive provides the intelligence needed for smooth, quiet, and efficient operation.

Advanced Vector Control for Smooth Lift Operation: The core strength of the ADrive lies in its advanced vector control technology. This ensures strong starting torque and precise motor management throughout the travel curve.

Compatible with Synchronous and Asynchronous Motors: Flexibility is a hallmark of the ADrive. It seamlessly drives standard asynchronous (induction) motors in both open and closed-loop configurations. It is also fully compatible with high-efficiency synchronous (gearless) motors, which require precise control for optimal performance.

Precision Ride Comfort and Energy Efficiency: By maintaining strict control over motor current and speed, the ADrive eliminates abrupt movements. Features like the anti-rollback function (which operates without a load cell) and automatic short-floor speed correction ensure passengers experience a smooth ride and accurate floor leveling. Furthermore, the system is designed to provide up to 40% savings in electricity consumption compared to traditional drive methods.

Key Technical Capabilities of the ADrive Series

Emergency Evacuation and Safety Features: Safety is paramount in lift design. The ADrive supports emergency evacuation operations by driving the motor with an external supply during a power failure. It can utilize a 60-120V battery pack or a 220VAC UPS to bring the car to the nearest floor. It effectively manages rollback prevention and monitors for over-speed conditions (>0.63 m/s).

Flexible Encoder Support and Connectivity: The unit comes with built-in support for incremental encoders (5V-24V, TTL, HTL, etc.). For applications requiring absolute position feedback, the optional ENCABIT-Plus card enables compatibility with EnDat, SSI, and SinCos absolute encoders. Serial communication via RS-485 ensures seamless integration with Arkel's ARL-500 control cards.

Choosing the Right Arkel ADrive Model: The series covers a wide power range to suit various lift capacities, from 4 kW up to 22 kW. Selecting the correct model depends on your motor's power rating and current requirements.

Product Table

| Parameter | Value |

| Product Type | VVVF Inverter (Frequency Drive) |

| Manufacturer | Arkel |

| Series | ADrive |

| Input Voltage | 3-Phase 400V (340V - 420V PE) |

| Power Options (kW) | 4kW, 5.5kW, 7.5kW, 11kW, 15kW, 22kW |

| Nominal Current Options (A) | 10A, 14A, 17A, 26A, 35A, 50A |

| Motor Compatibility | Synchronous (Gearless) & Asynchronous (Geared) |

| Control Type | Vector Control (Open/Closed Loop) |

| Encoder Support | Incremental (Standard); Absolute (EnDat, SSI, SinCos with Option Card) |

| Communication | RS-485 (Serial with ARL-500) |

| Protection Class | IP20 |

| Operating Temperature | -10°C to +50°C (Derating may apply) |

| Rescue Operation | Supports 60-120V Battery or 220VAC UPS |

| Certifications | CE, EMC Tested |

FAQ

Can the ADrive operate without a load cell?

Yes, the ADrive features an anti-rollback function that ensures smooth starts without requiring a load cell for weight measurement.

What types of encoders are supported?

The standard unit supports incremental encoders (TTL, HTL, 5-24V). For absolute encoders like EnDat, SSI, or SinCos, you need the additional ENCABIT-Plus card.

Does this drive support emergency rescue?

Yes, it enables evacuation by driving the motor with an external backup power supply, such as a 60-120V battery pack or a 220VAC UPS, during a main power failure.

Is it compatible with my existing lift controller?

The ADrive is designed for easy integration. It has specific RS-485 serial communication for Arkel ARL-500 controllers but can also work with other controllers via standard I/O terminals.

How do I update the firmware?

The device software can be updated using the ARKEL Software Updater program, ensuring you have the latest features and safety protocols.

What cooling method does the drive use?

The ADrive utilizes active cooling with low-noise fans to maintain optimal operating temperatures without excessive noise.

Suggested internal links:

Related products/accessories: