Fuji FRN11LM1S-4EA Frenic LIFT 11 kW Frequency Inverter (400V)

Same-Day Shipping!

- TYPE: FRN11LM1S-4EA (FRN 11 LM1S-4EA)

- Application Focus: Dedicated Frenic LIFT inverter designed for high-performance elevator motion, ensuring precise floor leveling and smooth acceleration/deceleration.

- Compatibility: Fully compatible with both standard three-phase induction (AC) motors and high-efficiency permanent magnet synchronous (PM) motors; requires encoder feedback for closed-loop vector control.

- Key Specification: 11 kW lift drive (400V class, 24.5 A nominal current) featuring a powerful 200% overload capacity (49.0 A) for 10 seconds to handle high-torque starts.

- Installation Note: Features a compact IP20 enclosure (220 x 260 x 215 mm) and includes the TP-G1-ELS multifunctional keypad for user-friendly setup in 12 languages.

- Warranty & Supply: Supplied as the European-specified ‘EA’ model; comes with the Fuji Electric standard manufacturer’s warranty (TBD, confirm ISF Elevator Shop policy).

Excluding Key Pad (TP-G1-ELS)

Guaranteed Safe Checkout

Download FRENIC-Lift User Manual (PDF)

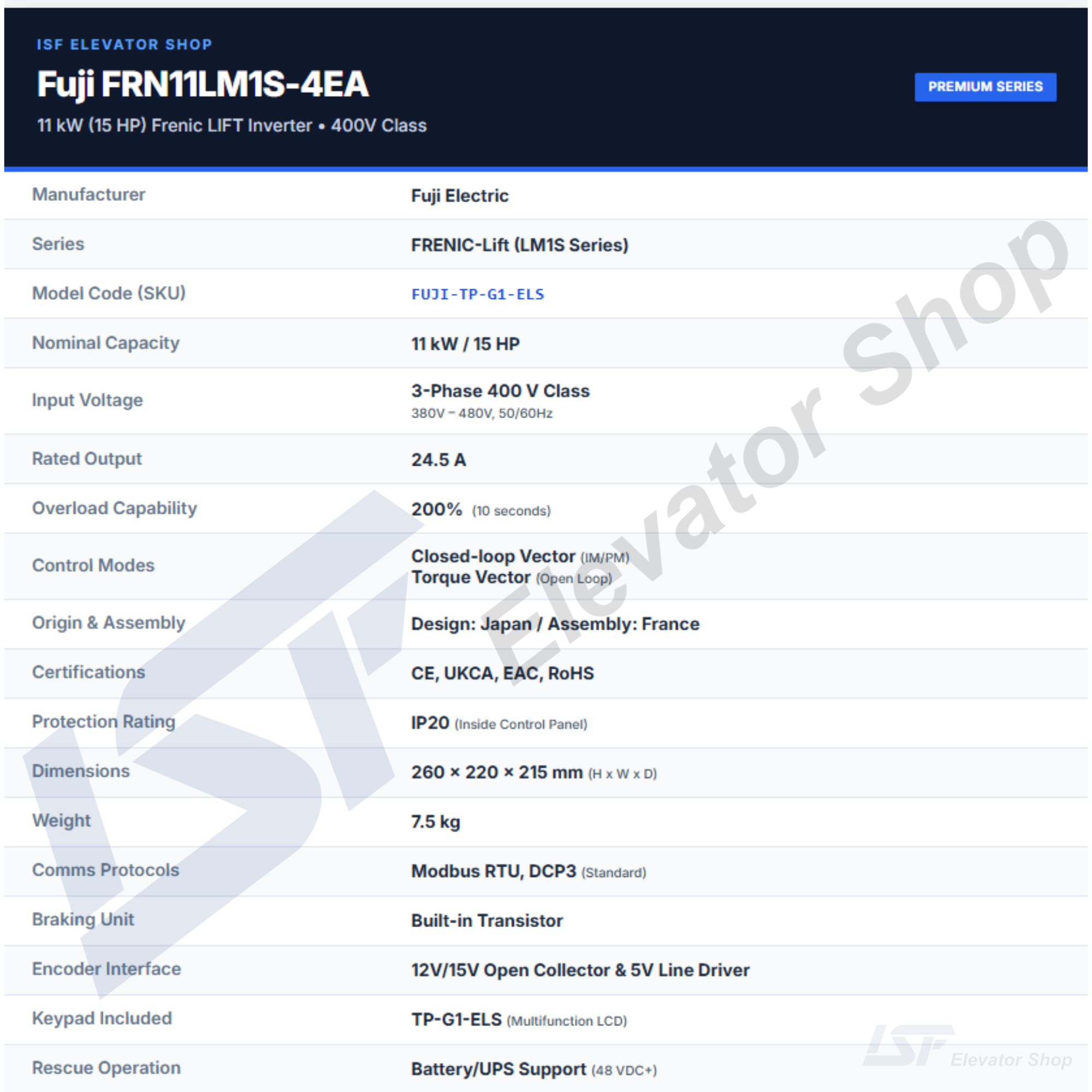

| Feature | Specification Details |

| Manufacturer | Fuji Electric |

| Series | FRENIC-Lift (LM1S Series) |

| Model Code (SKU) | FUJI-TP-G1-ELS |

| Nominal Motor Capacity | 11 kW / 15 HP |

| Rated Output Current | 24.5 A |

| Overload Capability | 200% of rated current for 10 seconds (High Overload) |

| Input Voltage Class | 3-Phase 400 V Class (380V – 480V, 50/60Hz) |

| Motor Compatibility | Induction Motors (Geared) & PM Synchronous Motors (Gearless) |

| Origin & Assembly | Design: Japan / Assembly: France (FR) |

| Certifications | CE (Europe), UKCA (UK), EAC (Eurasia), RoHS |

| Protection Rating | IP20 (Enclosed Type) |

| Dimensions (W x H x D) | 220 x 260 x 215 mm |

| Weight | 7.5 kg (Approx.) |

| Cooling Method | Forced Air Cooling (Fan) |

| Communication Protocols | Modbus RTU (RS-485), DCP03 (Standard) |

| Encoder Interface | Supports 5V/12V/15V encoders (Open Collector / Complementary) |

| Keypad | Includes TP-G1-ELS (Multifunction LCD, 12 Languages) |

| EMC Filter | Optional (External connection recommended for EN 12015 compliance) |

| Braking Unit | Built-in braking transistor (Connect external resistor to P(+) and DB) |

Precise Control for Unmatched Ride Comfort

Motor Compatibility (PM and Induction)

This versatile Fuji lift VVVF drive can operate both standard three-phase induction (geared) and high-efficiency permanent magnet synchronous (gearless) motors. This flexibility makes it an excellent choice for modernizations where the motor may be retained or replaced with a newer, high-efficiency type. The drive handles the specific, precise control requirements of PM motors necessary for accurate positioning.

Advanced Closed-Loop Vector Control

The FRN11LM1S-4EA is configured for closed-loop vector control, which requires an encoder for motor feedback. This precise control mechanism is essential for safety, accurate floor leveling, and the elimination of roll-back when starting, especially under heavy load conditions. It also includes built-in functions to manage lift-specific situations, such as evacuation operations supported by a battery or UPS source.

Technical Specifications and European Compliance

The Fuji FRN11LM1S-4EA is specified for the European market with the ‘EA’ suffix, indicating the 400V class and specific I/O configuration. It is rated for a continuous output of 11 kW, suitable for many mid-capacity traction systems.

Electrical Rating and Overload Capacity

Operating directly from a 3-phase, 400V supply (380V to 480V range), the drive has a nominal output current of 24.5 A. Critically, it provides a 200% overload capacity—49.0 A—for a duration of 10 seconds. This capability is vital for smooth, high-torque starts and managing dynamic load conditions without tripping.

Integrated Keypad and I/O Features

The drive is shipped with the TP-G1-ELS multi-functional keypad, simplifying parameter setting and diagnostics with support for 12 languages. It offers comprehensive input/output capability, including digital inputs, transistor digital outputs, and relay outputs for interfacing with the lift controller. Communication is supported via RS485 (Modbus RTU) and DCP03 protocols.

Installation Planning and Maintenance

The design of the Frenic-LIFT series focuses on longevity and ease of integration into existing lift control panels. Its robust components and long-life design contribute to a lower total cost of ownership over the product’s lifespan.

Physical Footprint and Environmental Rating

With dimensions of 220 mm (W) x 260 mm (H) x 215 mm (D) and a weight of 7.5 kg, the unit is relatively compact for an 11 kW drive. Its IP20 enclosure rating means it must be installed within a protected lift control panel environment, suitable for operating temperatures between -10°C and +45°C.

Essential Optional Accessories

To meet specific site requirements, the drive may require optional external components. For installations requiring high dynamic braking, an external braking unit must be connected. For compliance with strict electromagnetic compatibility (EMC) standards, an optional EMC filter is available and often necessary, depending on the lift controller configuration.

Selecting the Correct Fuji Lift Drive

The selection process must confirm the drive’s specifications match the motor and controller. Choosing the correct power rating is non-negotiable for system safety and performance.

Confirming Power and Motor Match

Ensure the 11 kW (15 HP) nominal power rating of the FRN11LM1S-4EA matches or slightly exceeds the nominal power rating of the elevator motor. Also, verify that the motor’s nominal current is compatible with the drive’s 24.5 A nominal and 49.0 A (10s) overload capacity.

Communication Protocol Checklist

Confirm that your existing or new lift controller utilizes a communication protocol compatible with the drive’s built-in RS485 (Modbus RTU) or DCP03 network interface. If the system relies on a CAN-based network, a different model with a different suffix (e.g., ‘E’ instead of ‘EA’) or an optional communication card may be required.

FAQ

How do I confirm compatibility with my elevator/controller/door system?

First, verify that your lift motor is rated for 11 kW (15 HP) or less and operates on a 400V 3-phase supply. Second, confirm that your existing or new lift controller uses an RS485 (Modbus RTU) or DCP03 protocol for communication. Finally, ensure you have an encoder installed on the motor shaft, as the FRN11LM1S-4EA requires closed-loop vector control for optimal ride quality.

What information should I provide before ordering?

To ensure correct application, please provide your motor’s full nameplate data (kW/HP, nominal current, voltage, type—AC Induction or PM Sync) and the brand and model of the elevator controller you will be using. This allows our technical team to verify the setup against the drive’s specifications.

Is this compliant with European standards (e.g., CE, EN81)?

The FRN11LM1S-4EA model has the ‘EA’ suffix, indicating it is configured for the European market. Fuji Electric drives are generally designed to meet relevant EU directives, but for specific project compliance, an external EMC filter is often required. We recommend you check local EN 81 standards regarding your full installation setup.

Can I install it myself or do I need a technician?

Due to the complexity of vector control parameterization and the safety-critical nature of lift equipment, installation and commissioning must be performed by a qualified elevator technician. Incorrect setup can lead to poor ride quality, premature component failure, or safety hazards.

What are common installation mistakes to avoid?

A common mistake is neglecting the correct sizing of the external braking resistor or unit, which is optional and not included. Another error is not correctly setting the motor parameters during the auto-tuning sequence, which is essential for the closed-loop vector control to function properly and deliver a smooth ride.

What is included and what’s not included?

The package includes the Fuji FRN11LM1S-4EA frequency inverter unit and the removable TP-G1-ELS operator keypad. The external braking unit, EMC filter, and any required braking resistors, fuses, or circuit breakers are not included and must be sourced separately.

What is the purpose of the 200% overload capacity?

The 200% overload capacity (49.0 A for 10 seconds) is necessary to manage high-torque demands. This occurs during the initial start of the lift under a full load and when the system is managing sudden load changes. This brief, powerful surge ensures the car accelerates smoothly without stalling or tripping the drive.

Does this model support emergency rescue operation?

Yes, the FRENIC-Lift series is designed to support the connection of an external battery or UPS system to facilitate controlled evacuation (rescue) operation during a power failure, a critical feature for lift safety standards.

Related products/accessories list:

Reviews

There are no reviews yet.